Description

At Global Chemical Alliance, quality materials are our priority. Our Zirconium Silicate sets the bar in terms of performance across versatile applications. It’s known for heat resistance, chemical toughness, and overall versatility. Key sectors like ceramics, refractories, coatings, and other specialized industries need our Zirconium Silicate. Why? It stands for reliability, consistency, and performance, boosting your manufacturing process.

Zirconium Silicate: What is it?

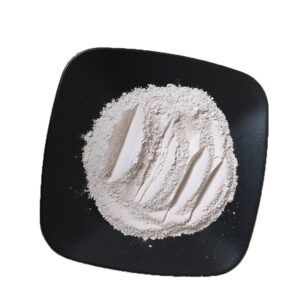

Zirconium Silicate (ZrSiO₄) is a natural mineral, once processed, it becomes a pure, fine, white powder. It’s a mix of zirconium oxide (ZrO₂) and silicon dioxide (SiO₂), boasting a high melting point and extraordinary corrosion resistance. This powder works wonders in environments with high temperatures and harsh chemicals. From ceramics to glass and other industrial uses, Zirconium Silicate is paramount where heat, wear, and corrosion resilience is required.

What does Zirconium Silicate do?

1. Ceramics and Porcelain: Zirconium Silicate is a game-changer in the ceramics industry. It’s the backbone of porcelain and advanced ceramics, offering unmatched strength and thermal stability. It adds to the hardness and durability of ceramic products. From tiles to electrical insulators, this robust powder is the magic ingredient.

2. Refractories/Foundry Applications: Zirconium Silicate loves heat. It’s the go-to material to produce things like furnace linings, crucibles, and components that experience intense heat and thermal shock. When casting metals, its superior durability makes it the prefered choice.

3. Coatings and Paints: A hero in the coatings industry, Zirconium Silicate enhances durability and performance of paints and surface treatments. It delivers smooth, abrasion-resistant finishes, perfect for protective industrial coatings. Whether for automotive, industrial, or decorative coatings, it gives wear resistance a boost.

4. Specialty Glass/Electronics: Specialty glass, optical lenses, high-performance glass, all use Zirconium Silicate due to its high refractive index and chemical stability. Electronics also utilize this additive for components needing high insulation and thermal shock resistance.

Why Global Chemical Alliance?

When you choose our Zirconium Silicate, we assure that it’s of high performance and outstanding quality. It is sourced from reliable suppliers and produced under stringent quality control, ensuring consistency and purity in every batch. Flexibly packaged and delivered to meet your business needs, we aim to support your operations in every way possible. Global Chemical Alliance cares about sustainability too. Our Zirconium Silicate is responsibly sourced, maintaining quality standards while minimizing environmental impacts.

Global Chemical Alliance: Here for You At the bleeding edge of chemical supply, Global Chemical Alliance offers products marked by quality, innovation, and reliability. Customer satisfaction and technical knowledge drive us, delivering product value that boosts your business objectives. With our Zirconium Silicate, get unmatched performance, strength, and quality. Choose Global Chemical Alliance and enhance your business in every step.

0.0 Average Rating Rated (0)